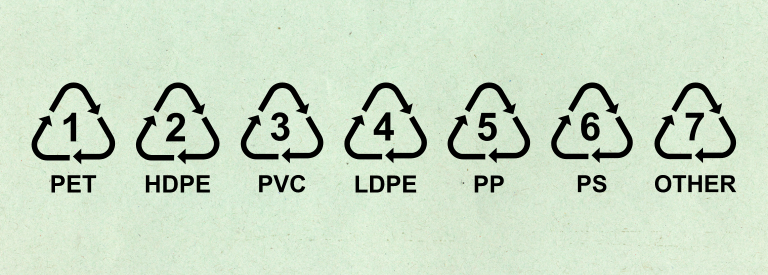

If you've ever turned a plastic bottle or container upside down, you've likely noticed a peculiar symbol: a triangle formed by three chasing arrows with a number inside. These are plastic recycling symbols, and they hold the key to responsible recycling.

Every day, millions of consumers worldwide come into contact with plastic products. From food packaging to household items, plastic plays a significant role in our daily lives. But with the ever-growing concern about environmental sustainability, understanding the importance of plastic recycling and the symbols that accompany it has become crucial.What Are The Seven Main Plastics?

Plastics have woven their way into our daily lives, making many tasks more convenient. However, not all plastics are created equal. To distinguish between these materials, we categorize them into seven primary types of plastic resins. Each of these has its distinct properties, applications, and recycling protocols. Let's delve deeper into these types and better understand their significance.

1. Polyethylene Terephthalate (PETE or PET)

- Properties: PETE, with its clarity, durability, and excellent gas and moisture barrier properties, is also lightweight, making it perfect for packaging.

- Common Uses: It's predominantly used in soft drink bottles, packaging for food, and textile fibers.

- Recycling: PET is broadly recycled. When reprocessed, it's often turned into fibers for items such as carpets or garments.

2. High-Density Polyethylene (HDPE)

- Properties: HDPE is known for its strength and resistance to moisture. It's also more opaque than PET.

- Common Uses: Items such as milk jugs, shampoo bottles, toys, and plastic bags are commonly made of HDPE.

- Recycling: HDPE is frequently recycled into products like plastic lumber, trash bins, and outdoor furniture.

3. Polyvinyl Chloride (PVC)

- Properties: PVC is versatile and known for its stability and resistance to oils and chemicals.

- Common Uses: PVC is found in a diverse range of items, from pipes and toys to bank cards, vinyl mats, and flooring.

- Recycling: PVC recycling is rarer due to potentially hazardous fumes upon heating. When it is recycled, PVC may be transformed into items like traffic cones or floorings.

4. Low-Density Polyethylene (LDPE)

- Properties: LDPE, more flexible than HDPE, has a low melting point and serves as an effective moisture barrier.

- Common Uses: It's typically employed in products like plastic bags, packaging films, squeeze bottles, and wire insulation.

- Recycling: Not all facilities accept LDPE for recycling. However, when recycled, it evolves into products like waste bin liners.

5. Polypropylene (PP)

- Properties: PP is tough and resistant to chemicals. It's also versatile with a high melting point.

- Common Uses: It is widely used in items such as yogurt containers, diapers, and auto parts.

- Recycling: PP can be recycled into automotive parts, industrial fibers, and other containers.

6. Polystyrene (PS)

- Properties: Polystyrene can either be rigid or foam-like. It acts as an insulator and barrier to moisture.

- Common Uses: It's commonly found in items like coffee cups and lids, food service articles, insulation, and egg cartons.

- Recycling: PS is accepted by fewer recycling centers, but when recycled, it's often transformed into insulation or other foam-based products.

7. Other

This category encompasses a variety of plastics that don't fit into the initial six categories.

- Polycarbonate Resins: Renowned for optical clarity and impact resistance, often utilized in products like eyeglasses and DVDs.

- Acrylic: Known for its transparency and resistance to shattering, acrylic products are used widely in light fixtures and nail extensions.

- Nylon: Durable and wear-resistant, found in items like clothes, ropes, and carpets.

- Fiberglass: Used for reinforcing plastics, enhancing their strength and durability.

- Polyactic Fibers (PLA & CPLA): Using renewable resources and offering biodegradable properties, they are commonly used in compostable products.

- Recycling: The recycling protocols for this category can vary widely depending on the specific type and local facilities.

Why Do These Recycling Symbols Matter?

Comprehending these recycling symbols carries paramount significance for a number of reasons that critically encompass our social responsibilities, efficiency in recycling processes, and consumer awareness.

Environmental Responsibility

Environmentally responsible behavior plays an irreplaceable role in our endeavors to create a greener planet. The key to preserving the health of our global environment rudimentarily starts with proper recycling. Consistent and correct recycling practices help inhibit an excess of plastics from detrimentally landing in our oceans, where they can inflict harm on diverse marine life. Over an extended period, these unattended plastics decompose into smaller fragments, forming microplastics. Microplastics pose an unsettling, yet often overlooked, threat to marine and terrestrial ecosystems. They can assimilate toxins, carrying potentially hazardous substances to every nook and cranny in our ecosystem when ingested by animals and marine life.

Efficient Recycling

Awareness and understanding of each recycling symbol play a key role in ensuring that each type of plastic finds its way to its designated recycling stream. This conscious segregation of waste contributes substantially towards enhancing the efficacy of recycling processes. The cleaner and more separated the contribution, the more enhanced the rate at which recycling can occur. This also minimizes the potential for contamination, often a significant problem resulting from the misdirection of certain plastic types, thereby ensuring a greater likelihood for plastics to be continually reused rather than ending up in a landfill or the natural environment.

Consumer Knowledge

An informed consumer, armed with the knowledge of the different types of plastics (via recycling symbols), has the potential to adjust their purchasing decisions in a manner that favors the environment. When consumers are able to comprehend the implications of each recycling symbol, they can then consciously steer towards purchasing items that use more easily recyclable or environmentally friendly plastics. This not only helps reduce the burden on recycling plants but also encourages manufacturers to utilize more sustainable and recyclable options, thus playing a crucial role in forming a cycle that encourages sustainability.

Recycling Process Overview

Understanding recycling symbols isn't just about knowing what material a product is made of; it also involves comprehending the recycling process itself. Once consumers deposit their recyclables into appropriate bins marked with these symbols, the recycling journey begins.

- Collection: Recycling begins with the collection of materials from households, businesses, and public spaces. This can involve curbside collection, drop-off centers, or other collection points.

- Sorting: After collection, recyclables are transported to recycling facilities, where they undergo sorting. This step involves separating different types of materials, including plastics, paper, glass, and metals, often through manual and automated processes.

- Processing: Once sorted, the recyclables are processed to prepare them for reuse. For plastics, this typically involves shredding or melting the material to form pellets or flakes. These processed materials can then be used to manufacture new products.

- Manufacturing: The processed materials are then used by manufacturers to produce new products. In the case of plastics, these materials can be used to create a wide range of items, from packaging and containers to textiles and construction materials.

- Consumer Use: The cycle continues as consumers purchase and use products made from recycled materials. By choosing these products, consumers contribute to closing the recycling loop and reducing the demand for virgin materials.

- End-Of-Life: Eventually, products made from recycled materials may reach the end of their useful life. At this stage, they can be recycled once again, completing the cycle and minimizing waste sent to landfills or incinerators.

Understanding the recycling process helps consumers appreciate the importance of recycling symbols and their role in promoting sustainable practices. By participating in recycling efforts and making informed choices, individuals can contribute to the conservation of resources and the protection of the environment.

Innovations In Recycling

Continued advancements in recycling technologies and approaches are driving progress towards a more sustainable future. Innovations such as chemical recycling, biodegradable plastics, advancements in material recovery facilities, closed-loop recycling systems, and blockchain technology for traceability are reshaping the recycling landscape. These innovations offer promising solutions to enhance efficiency, reduce waste, and mitigate environmental impact, paving the way for a circular economy where resources are used and reused in a continuous cycle.

Chemical Recycling

Chemical recycling, also known as advanced or molecular recycling, involves breaking down plastic materials into their molecular building blocks. Unlike traditional mechanical recycling, which melts and reshapes plastics, chemical recycling can convert plastics back into their original monomers or other useful chemicals. This process enables the recycling of plastics that are challenging to recycle conventionally, such as multi-layered packaging or contaminated plastics. Companies and research institutions worldwide are investing in chemical recycling technologies to close the loop on plastic waste and create a circular economy for plastics.

Biodegradable Plastics

Biodegradable plastics offer a promising alternative to traditional plastics derived from fossil fuels. These plastics are designed to break down naturally in the environment, reducing the accumulation of plastic waste in landfills and oceans. Innovations in biodegradable plastics include the development of materials derived from renewable resources, such as plant-based polymers like polylactic acid (PLA) or polyhydroxyalkanoates (PHA). Additionally, researchers are exploring ways to enhance the biodegradability of plastics through additives or microbial treatments, ensuring they break down efficiently without harming ecosystems.

Advancements In Material Recovery Facilities (MRFs)

Material recovery facilities play a crucial role in sorting and processing recyclable materials collected from households and businesses. Recent advancements in MRF technology have focused on improving sorting accuracy, increasing processing efficiency, and reducing contamination rates. Automated sorting systems equipped with advanced sensors and artificial intelligence can identify and separate different types of materials more effectively, resulting in higher-quality recyclables. Additionally, advancements in robotics and machine learning enable MRFs to handle a broader range of materials and streamline the recycling process from collection to resale.

Closed-Loop Recycling Systems

Closed-loop recycling systems aim to minimize the generation of waste by creating a continuous cycle of material use and reuse. In these systems, products are designed with recyclability in mind, and materials are collected, recycled, and reintroduced into the manufacturing process to create new products. Closed-loop systems promote resource conservation, reduce the reliance on virgin materials, and decrease the environmental impact of production and disposal. Companies across various industries, from electronics to fashion, are adopting closed-loop approaches to reduce their environmental footprint and create more sustainable products.

Blockchain Technology For Traceability

Blockchain technology is being explored as a tool to enhance traceability and transparency in recycling supply chains. By recording transactions and tracking the movement of materials from collection to processing to resale, blockchain systems can provide stakeholders with real-time visibility into the recycling process. This transparency helps identify inefficiencies, verify the authenticity of recycled materials, and ensure compliance with regulations and sustainability standards. Blockchain-enabled traceability also enhances consumer confidence in recycled products by providing assurance of their origin and environmental credentials.

Where Did Recycling Symbols & Numbers Come From?

The recycling symbols and accompanying numbers, formerly known as the Resin Identification Codes (RICs), originated in the 1980s as a response to the increasing need for plastic recycling standardization. The Society of the Plastics Industry (now known as the Plastics Industry Association) in the United States introduced these symbols in 1988. Their primary purpose was to provide recyclers and consumers with a consistent method to identify the resin content of plastic products. This categorization would aid in sorting plastics more effectively for the recycling process. The familiar triangle of chasing arrows was designed to represent the recycling loop, with each number from 1 to 7 signifying a different type of plastic resin. Over time, these symbols have become globally recognized, playing a vital role in plastic recycling efforts and consumer awareness.

Wrapping Up

The next time you encounter a plastic item, flip it over and check its recycling symbol. It's a small step, but with informed decisions and responsible recycling habits, we can all play a part in reducing the plastic footprint on our planet. Remember, while the symbols provide a guide, always check with your local recycling program to see what plastics they accept. Let's make a more sustainable future together!